ADCOR® 500T

Thick sectioned, conformable, hydro-expansive waterstop for preventing saline and brackish water entry through joints in concrete substructures

Product Description

A conformable, swellable polymer/butyl rubber waterstop strip that expands in contact with saline and brackish water. When fully encapsulated by poured concrete, the expansive forces form a seal against concrete faces. The seal resists hydrostatic pressure, stopping water from entering sub-structures.

ADCOR® is a unique product that has been specifically developed to provide higher performance than conventional bentonite or swellable rubber waterstops. Superior performance arises from:

- controlled, reproducible, volumetric expansion.

- cohesive strength maintained after volumetric expansion.

- malleable and plastic, enabling easy application to a variety of

- concrete profiles.

GCP can also uniquely provide continuity of swellable waterstops at construction joint/movement joint intersections. This is achieved by linking ADCOR® 500T with SERVITITE® AT 200 co-extruded hydrophilic/PVC waterstops (see detail).

Advantages

- Controlled volumetric expansion - reduces risk of concrete spalling.

- Conformable – can be installed onto a variety of irregular substrates.

- Retains cohesive strength at both original and expanded volume.

- No need for protective steel mesh.

- Resists at least 6 bar (60 m) hydrostatic pressure.

- Volumetric expansion over 140% in 8% salted water.

- Simple overlap jointing on site.

- Reproducible swell after wet – dry cycling.

- Can be easily joined to GCP PVC waterstops at movement joints.

- Unaffected by freeze/thaw cycling.

Applications

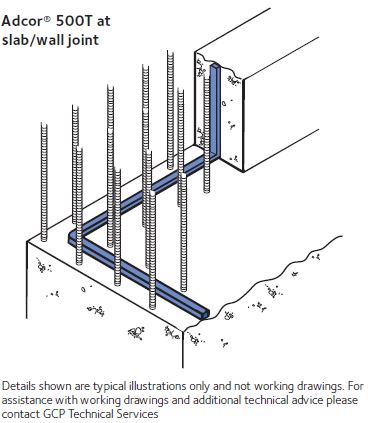

- Construction joints in in-situ concrete structures.

- Casting new concrete against existing.

- Floor slabs cast against diaphragm retaining walls, steel sheet piles and secant piled walls.

- Joints between floor slabs and pile caps.

- Pipe penetrations through floors and walls.

- Remedial ‘breaking out’ of concrete.

System Components

ADCOR® 500T

25 mm x 20 mm waterstop strip, supplied in 5 m rolls.

ADCOR® Mastic

A hydrophilic mastic for use as a bedding bead on irregular concrete surfaces prior to the application of ADCOR® 500T.

ADCOR® Adhesive MS

An adhesive for gluing ADCOR® 500T to smooth concrete, steel and plastic substrates. Supplied in cartridges for gun application.

Pak Adhesive™

A contact adhesive for gluing ADCOR® 500T to smooth concrete, steel and plastic substrates. Supplied in cans for brush application.

Supply

| ADCOR® 500T | 5 m rolls 6 rolls/carton 30 cartons/pallet pallet weight 700 kg |

|---|---|

| ADCOR® Mastic | 310 ml cartridge |

| ADCOR® Adhesive MS | 310 ml cartridge |

| Ancillary Products | |

| Large Secura Clips | Each |

Typical Properties

| Property | Typical Value |

|---|---|

| Profile size | 25 mm x 20 mm |

| Colour | Dark Blue |

| Volumetric expansion in 8% salted water | > 140% |

| Water pressure resistance | > 6 bar (60 m) |

| Density | 1.46 kg/dm3 |

| Weight | 0.7 kg/m |

| Maximum bend | 180° at 0°C |

| Application temperature range | -15°C to 60°C |

| Service temperature range | -45°C to 120°C |

| Minimum concrete cover | 70 mm |

| Minimum overlap | 100 mm |

All declared values shown in this data sheet are based on swelling component determined under laboratory conditions and with the product sample taken directly from stock in its original packing without any alteration or modification of its component parts.

Limitations

Not suitable for use in movement joints (use GCP co-extruded AT System). Not suitable for use with pre-cast concrete components.

Design

Waterstop networks must be continuous through all joints and penetrations if they are to be effective. If movement joints are necessary use SERVITITE® AT 200 or SERVISEAL® AT 240 PVC waterstops with co-extruded hydrophilic end bulbs. ADCOR® 500T can be easily jointed to these profiles (see detail).

Installation

- Concrete surfaces must be clean and free of all contaminants. Remove all concrete spatter and nibs.

- On irregular concrete faces gun a 10 mm bead of ADCOR® Mastic as a bedding for ADCOR® 500T.

Fixing Options

- Fix ADCOR® 500T using masonry nails 40 mm - 50 mm long with a washer 20 mm in diameter. Hilti EM6- 20-12 FP8 shot fired fixings with 6 mm nuts and 20 mm diameter washers may also be used. Fixings should be spaced at a maximum of 300 mm centres.

- ADCOR® Adhesive MS can be used on clean substrates, wire brushed to remove all dust, dirt, rust and other contaminants. The adhesive is damp surface tolerant but will not adhere to wet surfaces. Gun a 10 mm bead onto the substrate, and press ADCOR® 500T firmly into place.

- Pak Adhesive™ must be applied to dry substrates only. Apply by brush to both the substrate and ADCOR® 500T. Wait until both Surfaces are dry to touch, then press ADCOR® 500T firmly into place.

- At all movement joints link with GCP co-extruded AT System waterstops using Secura clips (see detail).

- All joints should be overlapped 100 mm, ensure full contact between jointed pieces.

- ADCOR® 500T can be bent around corners, however on complex geometry use ADCOR® Mastic as a gap filler.

- Any damaged sections should be removed and repaired with either a new section of ADCOR® 500T or a 25 mm min bead of ADCOR® Mastic.

- Keep ADCOR® 500T dry prior to pouring concrete.

Health and Safety

Read the product label and Safety Data Sheets before use. Users must comply with all risk and safety phrases. For health and Safety questions on this product please contact GCP.

gcpat.ae | United Arab Emirates customer service: +971 4 5139560

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

ADCOR, SERVISEAL and SERVITITE are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Alpharetta, GA 30009, USA

P. O. Box 5006, Office 2104, 21 Floor, The Exchange Tower, Opp. JW Marriott Marquis Hotel, Business Bay, Dubai – United Arab Emirates

This document is only current as of the last updated date stated below and is valid only for use in the UAE. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.ae. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-15

https://gcpat.ae/en-gb/solutions/products/joint-protection/adcor-500t