SERVITITE®

Internal PVC waterstop system for passive protection of movement joints and construction joints in reinforced concrete structures

Product Applications

SERVITITE® is an internally cast specially formulated PVC waterstop system manufactured in a range of sizes for use in reinforced concrete structures. Being cast into the centre of the concrete member, SERVITITE® waterstops will provide resistance against high hydrostatic pressure from both faces.

Product Advantages

- Robust profile - large solid circular end bulbs promote better anchorage and embedment into concrete and simplifies site jointing

- Flexible - will accommodate large movements during construction and service life

- Pliable - remains flexible at low temperatures

- Valve action - created by concrete shrinkage around end bulbs and adjacent fin formation

- Thick web - 10 mm thickness prevents folding over and displacement during concrete pouring

- Common section for easy installation - for construction and expansion joints subject to thermal movement and deflection.

Installation

A continuous waterstop network should be used at all joints to prevent the ingress of moisture using only factory produced fabrications for changes of direction or profile with site jointing limited to simple butted welds. Before concreting, waterstops must be clean and free from concrete laitance, oil, grease or any other contamination that might prevent a good waterstop to concrete bond.

Slab joints

SERVITITE® should be supported in specially prepared split stop-end formwork which holds the waterstop in the horizontal plane so preventing displacement and folding so that half of its width will be cast into the concrete approximately half way through the thickness of the slab.

Care must be taken to ensure that the waterstop is retained in the horizontal plane and that adequate compaction of concrete takes place below the web of the waterstop in order to avoid “honeycombing”. Lifting the waterstop during compaction to release entrapped air will assist in forming dense compacted concrete.

After stripping the formwork supporting the waterstop, the second half can be cast into the adjoining slab with similar precautions taken with regard to “honeycombing”.

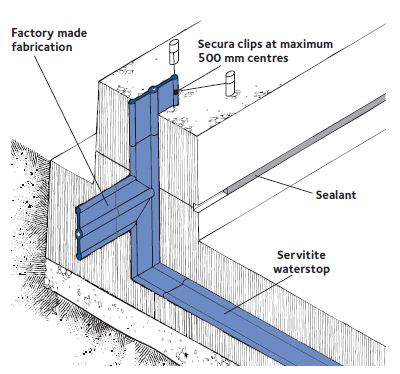

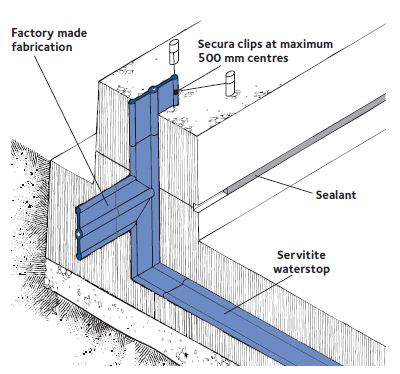

Wall joints

SERVITITE® must be supported in split-end form work as described for slab joints, with great care taken to ensure that the waterstop does not fold over under the weight of poured concrete. The waterstop may be securely wired to the reinforcing steel using the appropriate Secura Clips supplied, clipped over the end bulbs as shown overleaf.

| SIZE OF WATERSTOP | MINIMUM CONCRETE SECTION |

|---|---|

| SERVITITE® 150 m | 160 m |

| SERVITITE® 230 | 240 mm |

| SERVITITE® 305 | 315 mm |

Note: The above information assumes that waterstops are installed centrally in a joint.

Supply

| NORMAL CONSTRUCTION/MOVEMENT JOINTS | |

|---|---|

| SERVITITE® 150 | 7.5 m rolls wt 20 kg |

| SERVITITE® 230 | 5.0 m rolls wt 23 kg |

| SERVITITE® 305 | 5.0 m rolls wt 26 kg |

| Factory made junctions and fabrications | Available in sizes and configurations to suit the site requirements |

| Ancillary Products | |

| Secura Clip Small (20 mm) | Unit for SERVITITE® 150 |

| Secura Clip Large (25 mm) | Unit for SERVITITE® 230 and 305 |

| Equipment by GCP | |

| Jointing Jig | Jig SERVITITE® 150/230/305 |

| Welding Knives | Electric Knife 110v & 220v |

Equipment by Others: Fine tooth saw, wire brush, Stanley knife, 110v or 220v power source.

| PHYSICAL PROPERTIES | |

|---|---|

| Property | Typical Values |

| Tensile Strength | ≥ 14 N/mm² |

| Elongation at break | > 250% |

| Shore A Hardness | 80 ± 4 |

| Specific Gravity | 1.4 |

All test results shown in this data sheet are determined under laboratory conditions and with the product sample taken directly from stock in its original packing without any alteration or modification of its component parts.

Health and Safety

There is no legal requirement for a Safety Data Sheet (SDS) for Secura Clips or AEROFIL®. For health and safety questions on these products please contact GCP Applied Technologies.

For SERVITITE® read the product label and SDS before use. Users must comply with all risk and safety phrases. SDS’s can be obtained from GCP Applied Technologies or from our web site at gcpat.com.

Irritating fumes (Hydrogen Chloride) will be liberated when the product is heat welded. Ensure adequate ventilation.

NBS Specification Clause

Refer to Clause E40 310.

gcpat.ae | United Arab Emirates customer service: +971 4 5139560

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

AEROFIL and SERVITITE are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Alpharetta, GA 30009, USA

P. O. Box 5006, Office 2104, 21 Floor, The Exchange Tower, Opp. JW Marriott Marquis Hotel, Business Bay, Dubai – United Arab Emirates

This document is only current as of the last updated date stated below and is valid only for use in the UAE. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.ae. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2022-11-18

https://gcpat.ae/en-gb/solutions/products/joint-protection/servitite