PREPRUFE® 250 Membrane

Pre-applied waterproofing membrane that bonds integrally to poured concrete for use below foundation slabs and below ground cast-in-place walls on confined sites where single sided forms will be used

Product Description

GCP Applied Technologies (“GCP”) PREPRUFE® 250 pre-applied waterproofing membrane is a unique composite sheet comprised of a thick HDPE film, pressure sensitive adhesive and weather resistant protective coating. PREPRUFE® 250 membrane forms a unique, integral bond to poured concrete. This integral bond is specifically designed to provide a robust barrier to water, moisture and gas and prevents both the ingress and lateral migration of water.

Click here to download the PREPRUFE® 250 product brochure

Advantages

- Cold applied - No flame or hot works permits. No specialist equipment

- Simple and quick to install requiring no priming or fillets.

- Forms a continuous adhesive bond to concrete poured against it that is specifically designed to prevent water migration between the membrane and the concrete

- Continuous bond to poured concrete allows PREPRUFE® 250 membrane to remain bonded to the concrete even where ground settlement occurs

- Can be placed directly over properly prepared compacted soil

- Does not activate prematurely from water exposure during construction

- Fully adhered watertight laps and detailing

- Provides a barrier to water, moisture and gas - physically isolating the structure from the surrounding ground

- Impermeable - Perm rating less than 0.1 perms

- Can be applied to permanent formwork - Maximizes use of confined sites

- Allows for foot traffic immediately after application, ready for immediate placing of reinforcing steel

- Waterproofing is not reliant on confining pressures or hydration, waterproofing performance unaffected by wet/dry cycling

- Chemical resistance – Protects structure from salt and sulfate attack, and is effective in most types of soils and waters

Applications

PREPRUFE® 250 is an economical waterproofing solution intended for low hydrostatic pressure or intermittent water conditions. Applications include construction such as garages, plant rooms and utility grade basements.

For critical projects (i.e., occupied space and sensitive environments), GCP recommends the use of PREPRUFE® Plus with dual adhesive ZipLapTM technology. For high-risk and critical shotcrete applications, PREPRUFE® SCS - the only pre-applied waterproofing system designed specifically for shotcrete – is recommended for long-term waterproofing performance. See separate data sheets for more details.

System Components

Membrane

- PREPRUFE® 250 waterproofing membrane for horizontal use below concrete slabs or vertically against soil retention systems. Intended for use with cast-in-place concrete.

Ancillary Components (refer to the most current data sheets for all system components available on gcpat.ae or contact your local GCP representative.

- PREPRUFE® Tape HC – High temperature tape for covering cut edges, roll ends, penetrations and detailing

- PREPRUFE® CJ Tape HC — High temperature joint tape for construction joints and detailing

- BITUTHENE® liquid membrane — two component liquid membrane for sealing around penetrations and detailing

- ADCOR® waterstop - hydrophilic for joints in concrete walls and floors

- PREPRUFE® tieback covers — Preformed cover for soil retention wall tieback heads

- RE-INJECTO ® Re-Injectable injection hose for consecutive injection

Limitations of Use

- Approved uses only include those uses specifically detailed in this product data sheet and other current product data sheets that can be found at gcpat.com

- PREPRUFE® 250 membrane is not intended for any other use. Contact GCP Technical Services where any other use is anticipated or intended.

- PREPRUFE® 250 membrane is designed for in-service temperatures below 120°F (49°C)

- PREPRUFE® 250 membrane should not be used with conventional two-sided formwork. (See PREPRUFE® Technical Letter #TL-0013 “Forming Systems for use with PREPRUFE® Membranes”)

- Note that because of local regulations, test standards and customs, product literature and offerings may be different in various locations. If you have any questions or comments, please contact your local customer service office.

Safety and Handling

Users must read and understand the product label and safety data sheet (SDS) for each system component. All users should acquaint themselves with this information prior to working with the products and follow the precautionary statements. SDSs can be obtained by contacting your local GCP representative or office.

Storage

- Observe one-year shelf life and use on a first in, first out basis

- Store in dry conditions between 40°F (4.5°C)-90°F (32°C)

- Store off ground under tarps or otherwise protected from rain and ground moisture

- See PREPRUFE® Technical Letter #TL-0030 Shelf Life/Storage and Handling of GCP Waterproofing

Installation

Technical Support, Details and Technical Letters

The most up-to-date detail drawings and technical letters are available at gcpat.ae. For complete application instructions, please refer to the current GCP Applied Technologies Contractor Handbook and literature at (www.gcpat.ae). Documents in hard copy as well as information found on websites other than www.gcpat.ae may be out of date or in error. Before using this product it is important that information be confirmed by accessing www.gcpat.ae and reviewing the most recent product information, including without limitation product data sheets, contractor manuals, technical bulletins, detail drawings and detailing recommendations. Please review all materials prior to installation of PREPRUFE® 250 membrane.

Support is also available by full-time technically trained GCP Applied Technologies field sales representatives and technical service personnel, backed by a central research and development technical services staff. For technical assistance with detailing and problem solving, please contact your local GCP representative.

Temperature Requirements

- PREPRUFE® 250 membrane can be applied at temperatures of 25°F (-4°C) or above. When installing PREPRUFE® 250 membrane in cold or marginal weather conditions <55°F (<13°C), the use of PREPRUFE® Tape is required at all laps and detailing. All surfaces to receive PREPRUFE® Tape must be clean

- PREPRUFE® 250 membrane is designed for in-service temperatures below 120°F (49°C).

Substrate Preparation

All surfaces - It is essential to create a sound and solid substrate to eliminate movement during the concrete pour. Substrates must be regular and smooth with no gaps or voids greater than 0.5 in. (12 mm). Grout around all penetrations such as utility conduits, etc. for stability.

Horizontal - The substrate must be free of loose aggregate and sharp protrusions. Avoid curved or rounded substrates. When installing over earth or crushed stone, ensure substrate is well compacted to avoid displacement of substrate due to traffic or concrete pour. The surface does not need to be dry, but standing water must be removed.

Vertical - Use concrete, plywood, insulation or other approved facing to sheet piling to provide support to the membrane. Board systems such as timber lagging must be close butted to provide support and not more than 0.5” (12mm) out of alignment.

Membrane Application

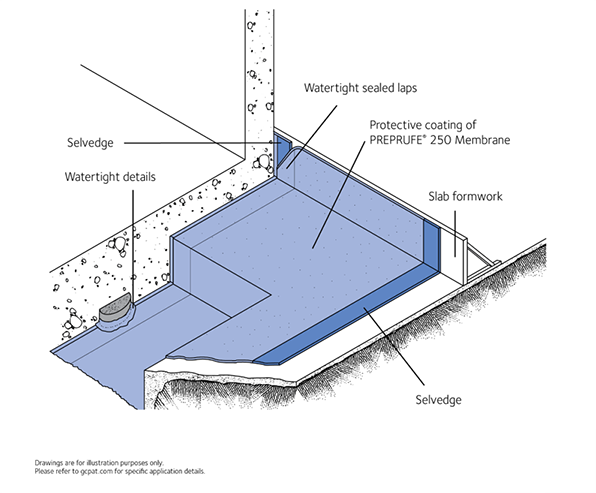

PREPRUFE® 250 membrane is supplied in rolls 4 ft. (1.2m) wide, with a selvedge on one side to provide self-adhered laps for continuity between rolls. The rolls of PREPRUFE® 250 membrane and PREPRUFE® Tape are manufactured with a disposable plastic release liner, which must be removed before placing reinforcement and concrete. NOTE that the release liner must also be removed before application of any required tapes and from all surfaces where a bond between layers is to be formed.

Horizontal substrates – PREPRUFE® 250 membrane can be applied horizontally to smooth prepared concrete or well rolled and compacted earth or crushed stone substrate. Place the PREPRUFE® 250 membrane HDPE film side to the substrate with the clear plastic release liner facing towards the concrete pour. End laps should be staggered to avoid a build-up of layers. Leave plastic release liner in position until overlap procedure is completed. When completed, remove release liner. When installing over carton forms, contact your local GCP representative.

Accurately position succeeding sheets to overlap the previous sheet 3 in. (75 mm) along the marked selvedge. Ensure the underside of the succeeding sheet is clean, dry and free from contamination before attempting to overlap. Peel back the plastic release liner from between the overlaps, allowing the two overlapped layers to bond together. Ensure a continuous bond is achieved without creases and roll firmly with a heavy roller. Completely remove the plastic liner to expose the white protective coating. Any initial tack will quickly disappear.

Notes: PREPRUFE® 250 membrane can be returned up the inside face of slab formwork. This allows for a fully bonded system by tying in with BITUTHENE® self-adhered membrane as and when applied to vertical structural surfaces after removal of formwork. Rebar Chairs: See PREPRUFE® Technical Letter #TL-0015 “Rebar Chairs on PREPRUFE® Membranes.”

Vertical substrates – PREPRUFE® 250 membrane can be applied vertically to permanent formwork or adjoining structures. Concrete should then be cast directly against the adhesive side of the membrane. The membrane may be installed in any convenient length. Proper installation requires that the clear plastic release liner must be facing towards the concrete pour. (Note that the release liner must be removed prior to pouring concrete.) The membrane must be shingle overlapped a minimum of 3” (75mm) All laps over cut edges must be taped using PREPRUFE® Tape.

Vertically placed sheets can be held in place using fasteners appropriate to the substrate. Fastening can also be made through the selvedge overlap area using a small and low-profile head fastener so that the membrane lays flat and allows firmly rolled overlaps. Fasteners should be placed in the selvedge approximately 0.5”(12.5mm) from the edge of the membrane. The adhesive selvedge of successive membrane sheets must completely cover any fasteners by a minimum of 1 in. (25mm). After rolling, immediately remove the plastic release liner. When placing successive sheets, ensure the underside of each succeeding sheet is clean, dry and free from contamination before attempting to overlap. After placement, roll the membrane firmly to ensure a watertight seal.

Roll ends and cut edges – Overlap all roll ends and cut edges by a minimum 3 in. (75 mm) and ensure the area is clean and free from contamination, wiping with a damp cloth if necessary. Allow the membrane to dry and apply PREPRUFE® Tape centred over the lap edges and roll firmly. Immediately remove plastic release liner from the tape.

Membrane Repair

Inspect the membrane before installation of reinforcement steel, formwork and final placement of concrete. The membrane can be easily cleaned by low pressure power washing if required. Repair damage by wiping the area with a damp cloth to ensure the area is clean and free from dust and other contaminants, and allow the membrane to dry. Repair small punctures and slices 0.5 in. (12 mm) or less by applying PREPRUFE® Tape centred over the damaged area. Repair cuts, punctures and holes larger than 0.5 in. (12mm) by applying a patch of PREPRUFE® membrane. Extend the patch 6 in. (150 mm) beyond the damaged area. Seal all edges of the patch with PREPRUFE® Tape. Where exposed selvedge has lost adhesion or laps have not been sealed, ensure the area is clean and dry and cover with fresh PREPRUFE® Tape. Any areas where the adhesive layer has been damaged should be covered with PREPRUFE® Tape. All PREPRUFE® Tape must be rolled firmly and the tinted release liner removed.

Slices or relief cuts can be butted or overlapped and repaired by applying PREPRUFE® Tape centred over the edge of the overlap or centre of the butt joint. Where it is not possible to create a butt joint or overlap, repair/patch with fresh membrane and PREPRUFE® Tape as detailed above.

Pouring of Concrete

Prior to placing concrete ensure the plastic release liner is removed from all areas of PREPRUFE® 250 membrane and tape.

Under most climatic conditions, concrete should be poured within 56 days of membrane installation. Where ambient temperatures will exceed 100ºF (38°C) for more than a total of seven days, concrete should be placed within 42 days of installation of the membrane. Concrete must be placed and compacted carefully to avoid damage to the membrane. Never use a sharp object to consolidate the concrete.

Removal of Formwork

A minimum concrete compressive strength of 3000 psi (20 N/mm2) is required prior to stripping formwork supporting PREPRUFE® 250 membranes. Premature stripping may result in displacement of the membrane and/or spalling of the concrete. (see PREPRUFE® Technical Letter #TL-0017 “Removal of Formwork Placed against PREPRUFE® 250 Membranes”.)

After removal of the formwork and prior to backfilling, all exposed PREPRUFE® 250 membrane must be protected from damage with an approved protective course.

Supply

| Dimensions (Nominal) | PREPRUFE® 250 Membrane | PREPRUFE® Tape |

| Roll size1 | 1.2 m x 35 m (4 ft. X 115 ft.) | 100 mm x 15 m |

| Roll weight | 42 kg (92 lbs.) | 2 kg (4.4 lbs.) |

| Minimum side/end laps | 75 mm (3 in.) | 75 mm (3 in.) |

Note#1 Individual roll length may vary +/-1%

Physical Properties

| PROPERTY | TYPICAL VALUE PREPRUFE® 250 | TEST METHOD |

| Color | White | |

| Thickness | 0.030 in. (0.8 mm) | ASTM D3767 |

| Lateral Water Migration Resistance |

Pass at 231 ft (71 m) of hydrostatic head pressure |

ASTM D53851 |

| Low temperature flexibility | Unaffected at -20°F (-29°C) | ASTM D1970 |

| Resistance to hydrostatic head | 231 ft (71 m) | ASTM D53852 |

| Elongation | 300% | ASTM D4123 |

| Tensile strength, film | 4000 psi (27.6 MPa) | ASTM D412 |

| Crack cycling at -9.4°F (-23°C),100 cycles | Unaffected, Pass | ASTM C836 |

| Puncture resistance | 135 lbs (600 N) | ASTM E154 |

| Peel adhesion to concrete | 4 lbs/in. (700 N/m) | ASTM D9034 |

| Lap peel adhesion | 4 lbs/in. (700 N/m) | ASTM D18765 |

| Permeance to water vapor transmission | 0.01 perms (0.6 ng/(Pa x s x m2)) | ASTM E96, method B |

2. Hydrostatic head tests of PREPRUFE® membranes are performed by casting concrete against the membrane with a lap. Before the concrete cures, a 0.125 in. (3 mm) spacer is inserted perpendicular to the membrane to create a gap. The cured block is placed in a chamber where water is introduced to the membrane surface up to the head indicated.

3. Elongation of membrane is run at a rate of 2 in. (50 mm) per minute.

4. Concrete is cast against the protective coating surface of the membrane and allowed to properly dry (seven days minimum). Peel adhesion of the membrane to the concrete is measured at a rate of 2 in. (50 mm) per minute at room temperature.

5. The test is conducted 15 minutes after the lap is formed and run at a rate of 2 in. (50 mm) per minute at 72°F (22°C).

6. Lab to lab variation can be +/- 10%

gcpat.ae | United Arab Emirates customer service: +971 4 5139560

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

PREPRUFE, BITUTHENE, and HYDRODUCT are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2020 GCP Applied Technologies Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Alpharetta, GA 30009, USA

P. O. Box 5006, Office 2104, 21 Floor, The Exchange Tower, Opp. JW Marriott Marquis Hotel, Business Bay, Dubai – United Arab Emirates

This document is only current as of the last updated date stated below and is valid only for use in the UAE. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.ae. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2022-11-18

https://gcpat.ae/en-gb/solutions/products/preprufe-pre-applied-waterproofing-solutions/preprufe-250-membrane